HOW TO make a Leather Item

Chapter 2: Leather Cutting

Did you know that a wallet could be composed of more than 50 different small pieces? Each of the pieces must be cut with the greatest precision in order to get the highest quality. Leather goods manufacturers in Ubrique (Andalusia) are using three main cutting methods.

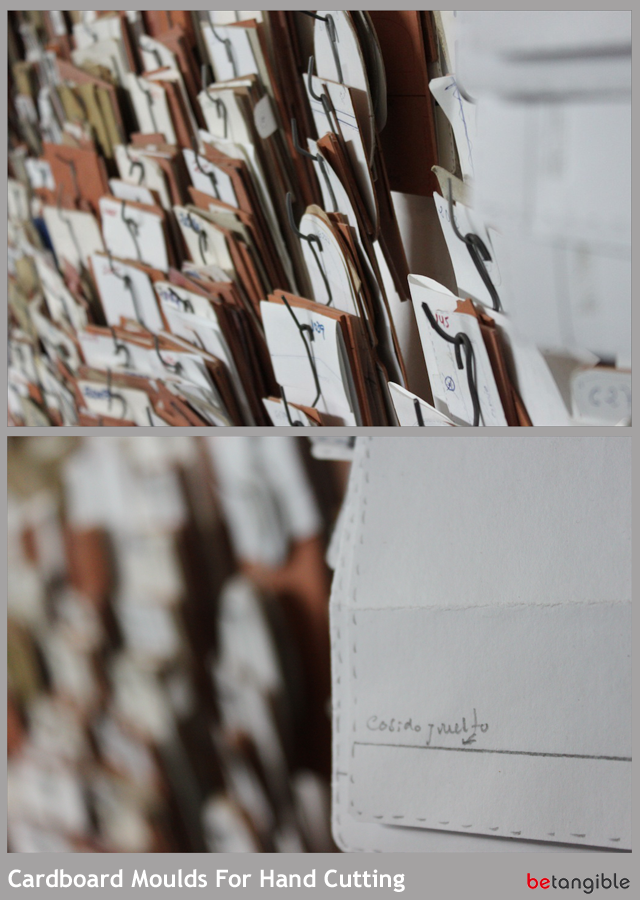

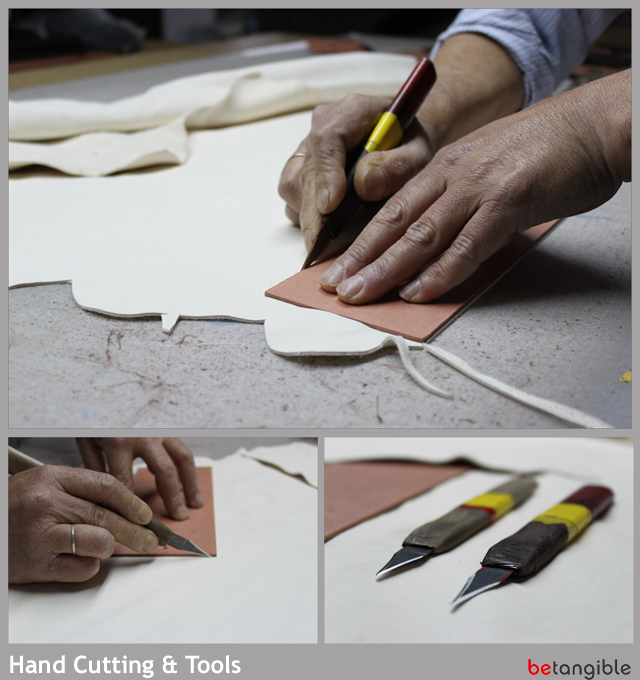

- · Hand cut: Only the most skilful cutters are able to cut the leather by hand. In order to do this, a cardboard pattern and a sharp blade are used. The cutter must also be able to select the proper areas of the leather for each part of the leather item.

- · Die Cutting (Press Machine): When there is a considerable amount of items to be produced, a metal cutting piece is made for each piece of which the leather item is composed. A press machine is used to cut the leather

- · Automatic cutting system (CAD/CAM Technology) : Although the investment in this kind of technology is very high, automatic-cutting system provide manufacturers with a multifunctional tool for the current times. CAD/CAM technology is really helping manufacturers to meet the needs and demands of the market since it helps you develop critical processes in the manufacturing of a leather item such as pattern making, easy pattern amendment and prototype & sample making. Automatic cutting systems are ideal for small batch production.

There are no comments