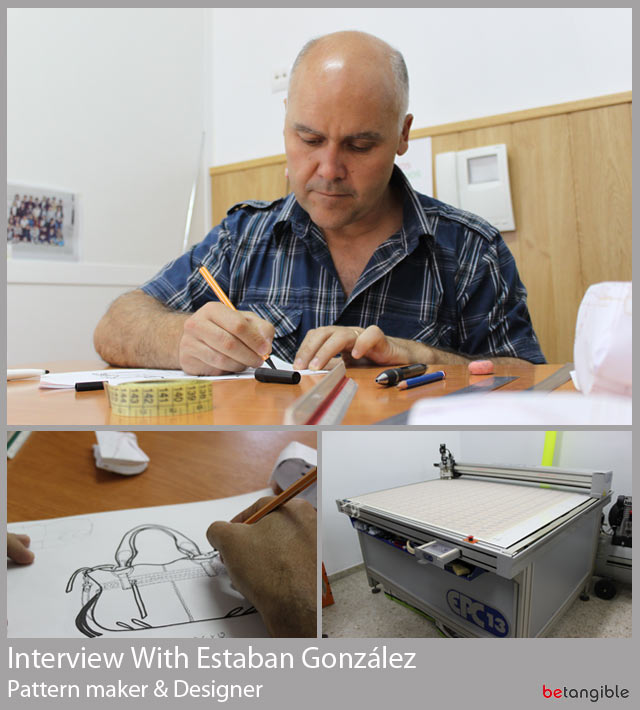

Interview with… Esteban González – Pattern Maker & Designer

Today, we want to present you the third interview of the series “Interview with…” . This time it is the turn of Esteban González. Esteban runs a company that specialises in pattern and prototype making and is responsible for one of Betangible’s prototyping workshops. Let’s get to know a bit more about his work…

Betangible: From where do you usually start your work? What is the first step?

Esteban Gonzalez:

I can start the process from three different points of view:

- A detailed drawing with measurements and information

- A simple sketch

- Some pictures that will be used as an inspiration for the new style

- A real bag to which I have to make modifications so that the new style can communicate the concept of the collection.´

Betangible: Which are the tools that you use in your workshop?

EG: The tools that I use are mainly a ruler, a scale, my computer with a CAD programme and a cutting plotter.

Betangible: How did you become a pattern maker and a designer?

EG: Well, my sister is an architect and I used to see her making drawings, creating new concepts for buildings and working with CAD/CAM technology. I learned quite a lot of things from her. When I was in my 20s, I started working for a leather goods manufacturer in Ubrique and I found out that I could apply my knowledge about volumes and shapes into the leather goods industry. Several years later, I decided to run my own business in which I could apply my deep knowledge about both field, the manufacturing of leather goods and pattern making.

Betangible: What type of clients do you have?

EG: They are mainly from Spain (designers and leather goods manufacturers). However I decided to create a webpage in order to offer my services in other countries. On my website, I also want to share my creations and designs so that they can be used for other people’s collections.

Betangible: What are the main steps for making a pattern?

EG: I follow the following steps_

1st. Interpretation of the style (measurements, main features, …) and the understanding of the concept of the whole collection.

2nd. I implement all the parts into my CAD application (Front part, bottom part, gusset, handles, strap, …) and I make three different sets of patterns:

- Patterns of design: For the assembly of the leather item. I always mark the stitch width and other important information for the manufacturer. This will avoid future issues in the workshop.

- Cutting patterns: For the main material (leather, canvas, …) in which I make marks for the thinning.

- Patterns for reinforcements and lining: Specifying the proper materials to be used so that we can get the desired effect, volume, stiffness,…

3rd. Nesting of the different pieces for cutting

4th. Cutting of the cardboard using a cutting plotter.

I decided to work this way because I aim at minimising the risks of a mistake in the workshop that will eventually lead to a less cost-effective production.

Betangible: Is it a quick process?

EG: It depends on the item. I must say that CAD/CAM technology facilitates the process very much and also makes the whole process more accurate.

Betangible: What types of leather goods are more demanded?

EG: I can say that they are mainly leather bags. So, I can say that…

- 80 % bags

- 20 % small leather goods

I have also developed other less comon leather ítems such as caps, leather goods for pets (carying bags, cushions, …) etc.

There are no comments